Melding of Technology and Craftsmanship

The « Michel BRAS » series has been created by finding a perfect balance in the combination of the most advanced technology and the craftsmanship of experienced artisans.

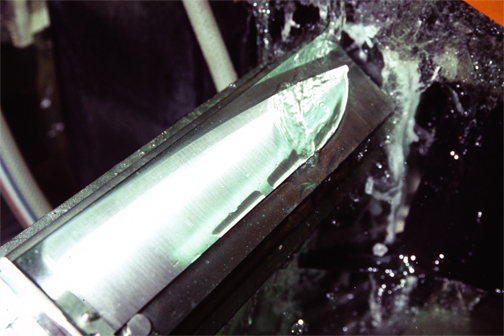

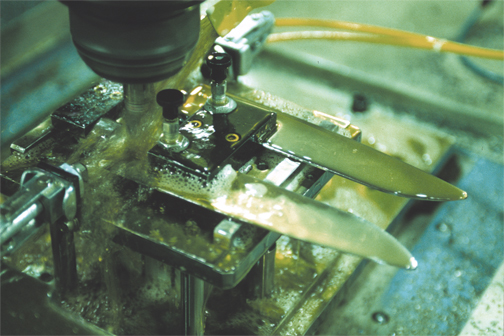

First stage in the making of the knife: grinding and polishing

The first stage in making a knife consists in making it look like a knife! This requires grinding and polishing a blade of equal thickness so that from the tip all the way along the blunt upper edge you know you are in the presence of a knife. To polish the surface pure water is poured over to the blade while a cylindrical whetstone rotating at high speed grinds it into shape. A second polishing is done by hand to give its surface a sleek, satiny finish.

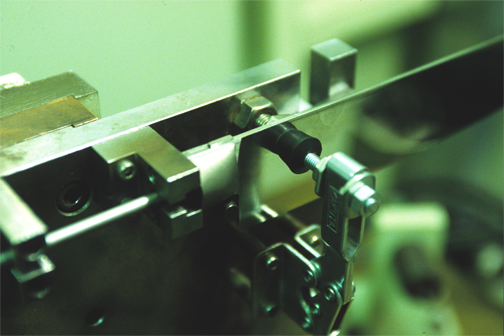

Soldering and polishing the base blade that supports the blade

The blade base is the core of the knife, binding together the blade and the handle. It must be soldered on and polished after the superfluous parts have been eliminated. The angle and shape of the blade base are finished differently according to the particular qualities of the ten varieties of blades and handles.

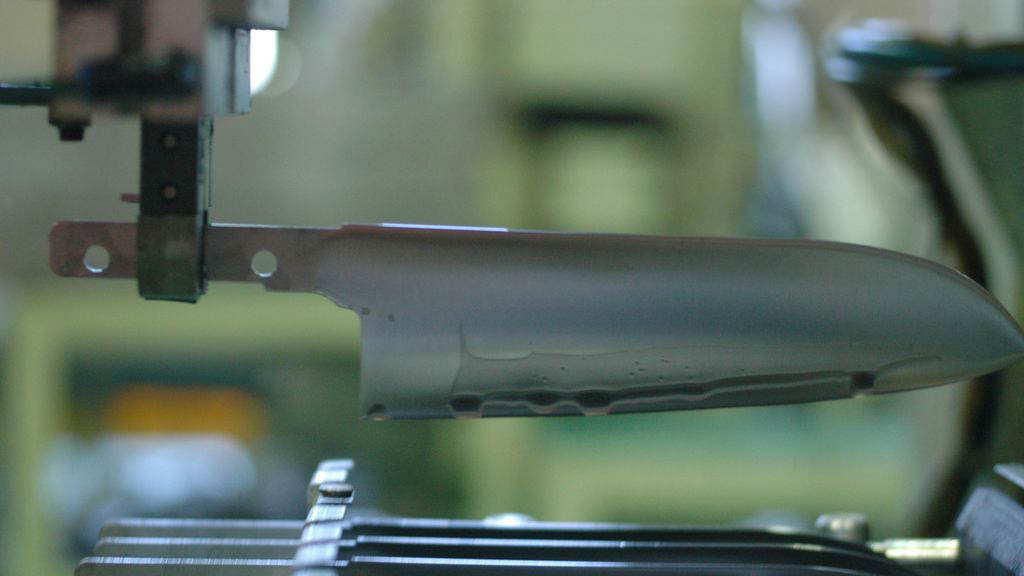

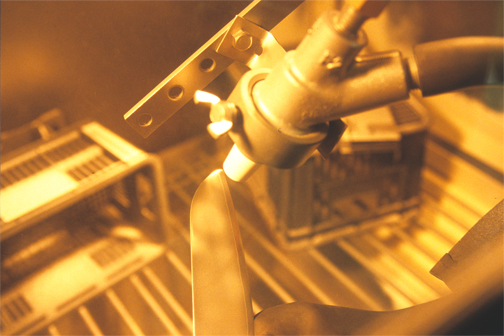

Sandblasting for beauty

The mysterious matte appearance of the Michel Bras knives is made possible by a method called "shotblast." Very fine glass beads are blown against the blade at extremely high pressure. The quality of the result depends on the precise hand movements of the artisan holding the blade during this operation.

Assemblage by hand

Assemblage of the blade and the handle, and of the handle and the metal end piece, are done by hand. In particular, the assemblage of the chestnut-shaped handle and end piece leaves no room for error. These are matched repeatedly until they fit together exactly.

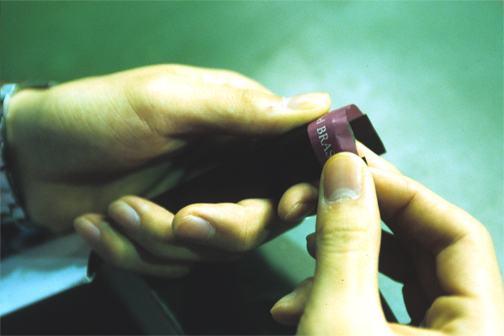

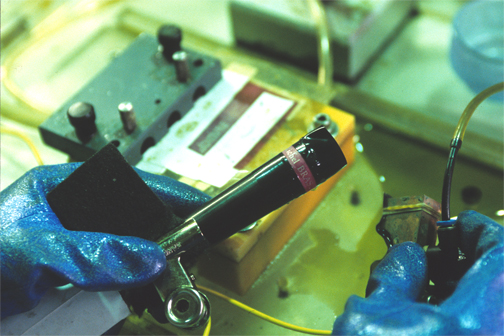

Etching on the brand name

The brand mark , "Michel Bras. Laguiole, France," is proudly etched on the metal end piece that gives the blade its perfect balance. The stencil with the lettering removed is aligned with the chestnut-shaped metal end piece and carefully glued on, and then the mark is etched on by electrolysis. It takes two experienced artisans an hour to complete the process for just a few knives.

Breathing life into the blade: the final sharpening

The final sharpening process makes it possible to produce cutting edges suitable for a variety of purposes. First comes water polishing using a rotating whetstone on which water is poured. Then the blade undergoes a leather polishing using a strip of cow hide on a rotating cylinder. The combination of these two techniques results in a blade of exceptional sharpness and finesse. Skilled technicians watch over the whole process from beginning to end.

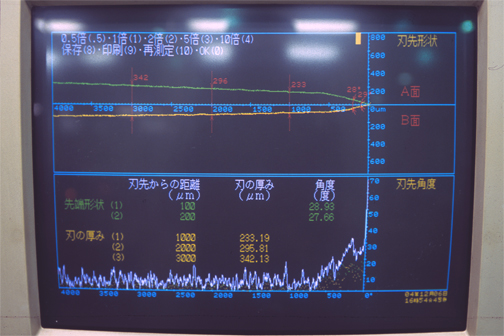

Quality controls measured in μm

Strict quality control is maintained throughout the process. There is also a final random check. A diamond-pointed needle, with the help of a computer, is used to determine whether the shape, angle, thickness of the blade edge-- the soul of a knife - are up to standard. The degree of precision is measured to within a thousandth of a millimeter (μm). Finally, further checks of every element are carried out before delivery.

After the completed Michel BRAS knives have passed through over 37 processes, any oil residue is eliminated and they are placed in their sheaths. An alkaline ion rinse is used rather than organic fluids for eliminating these residues.